- Matissart, Leading Blow Mold Maker, invests every year in research and development.

- One Objective = anticipate the expectations of our customers and offer them innovative molds to save their resources.

- We have cutting-edge technology with calculation allowing mechanical, thermal and fluidic simulations.

- We are the only extrusion blow mould maker to be approved by Crédit Impôt Recherche (Research Tax Credit), which allows our customers to benefit from tax reductions by working with MATISSART on innovative projects.

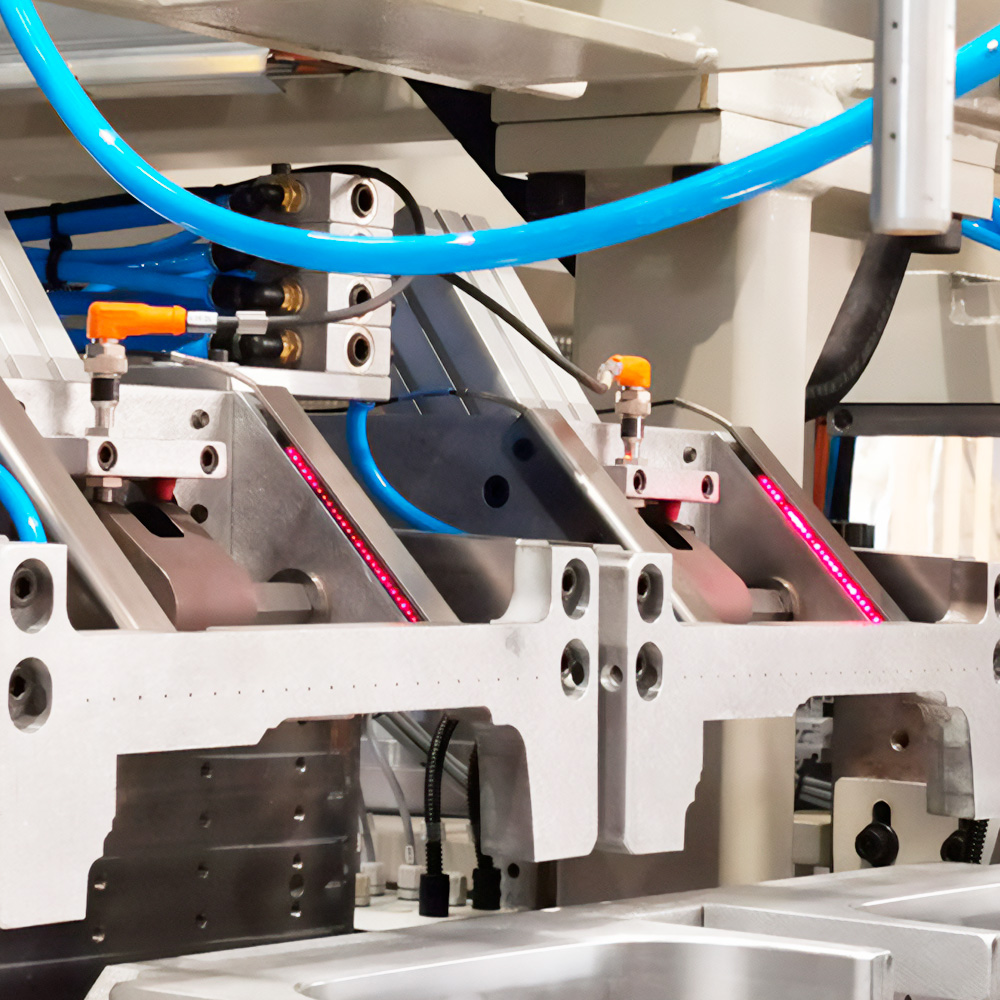

3D JET COOLING

Cooling system allowing drastic optimization of cycle times while reducing energy consumption.

Patented deflashing system for stackable drums

Patented deflashing system combining innovative kinematics coupled with a high-velocity sensor system ensuring the detection of the handle scraps of stackable jerrycans..

Unscrewing blow pin

Unscrewing blow pins operated by electric or hydraulic motors allowing, on a top blowing machine, to manufacture jerrycans with internal thread necks.

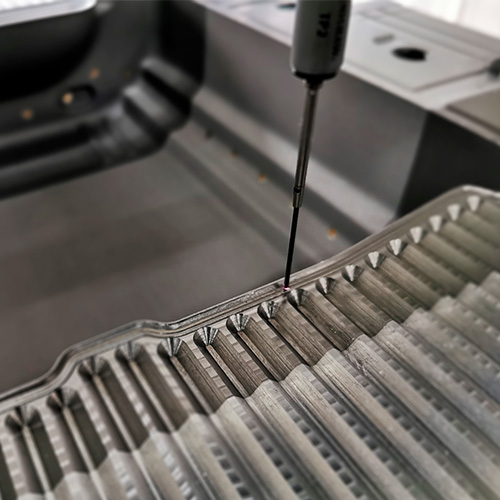

Parting line

Specific parting line design that allow excellent weldings in single layer or coex, minimizing the clamping force and increasing the life of the molds.

Static or deformable dies or pins

We master the calculation of ovality of dies or pins. MATISSART EASY TUNE (MET) allows the adjustment of ovality on machine simply and precisely.