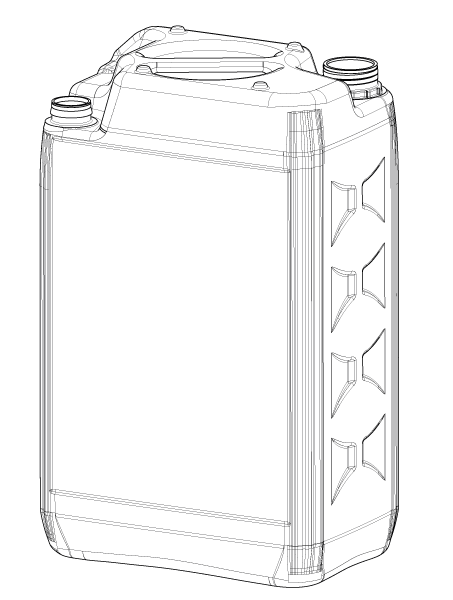

Often associated with everyday packaging, plastics also play a strategic role in industry through a discreet yet essential player: the large plastic drum. Used for the storage and transport of chemicals, agrochemicals, lubricants and solvents, it combines safety, strength and innovation.

Designed to withstand aggressive substances, ensure leak-tightness and meet demanding logistical requirements (stackability, palletisation, handling), these containers must comply with strict international standards. Their manufacture relies on advanced processes such as extrusion blow moulding and the use of high-performance polymers. In addition, multilayer barrier structures are increasingly being developed to enhance protection against aggressive liquids and gases.

In response to environmental challenges, industrial drums are evolving towards greater sustainability: the incorporation of recycled materials, the development of reusable models, and dedicated recycling streams. This transition requires constant innovation and production tools capable of combining technical performance with new sustainability requirements.

In this context, the role of precision blow moulds is central: they determine product quality, production speed and process reliability. Building on its recognised expertise in mould design, Matissart supports plastics manufacturers in producing ever more efficient industrial drums, thanks to advanced technologies such as 3D JET COOLING™.