Metallurgy has undergone major technological acceleration over the past two years. Advances in materials, digital simulation, and machining processes are opening new possibilities for manufacturers of technical molds.

1. New High-Performance Steels: A Silent Revolution

Next-generation metalloplastic steels (modified H13, PM steels – powder metallurgy, high-conductivity steels) offer:

- improved thermal resistance,

- superior abrasion performance,

- higher dimensional stability,

- enhanced machinability.

These materials significantly increase mold lifetime, particularly for demanding productions such as high-speed HDPE bottles or technical hollow bodies.

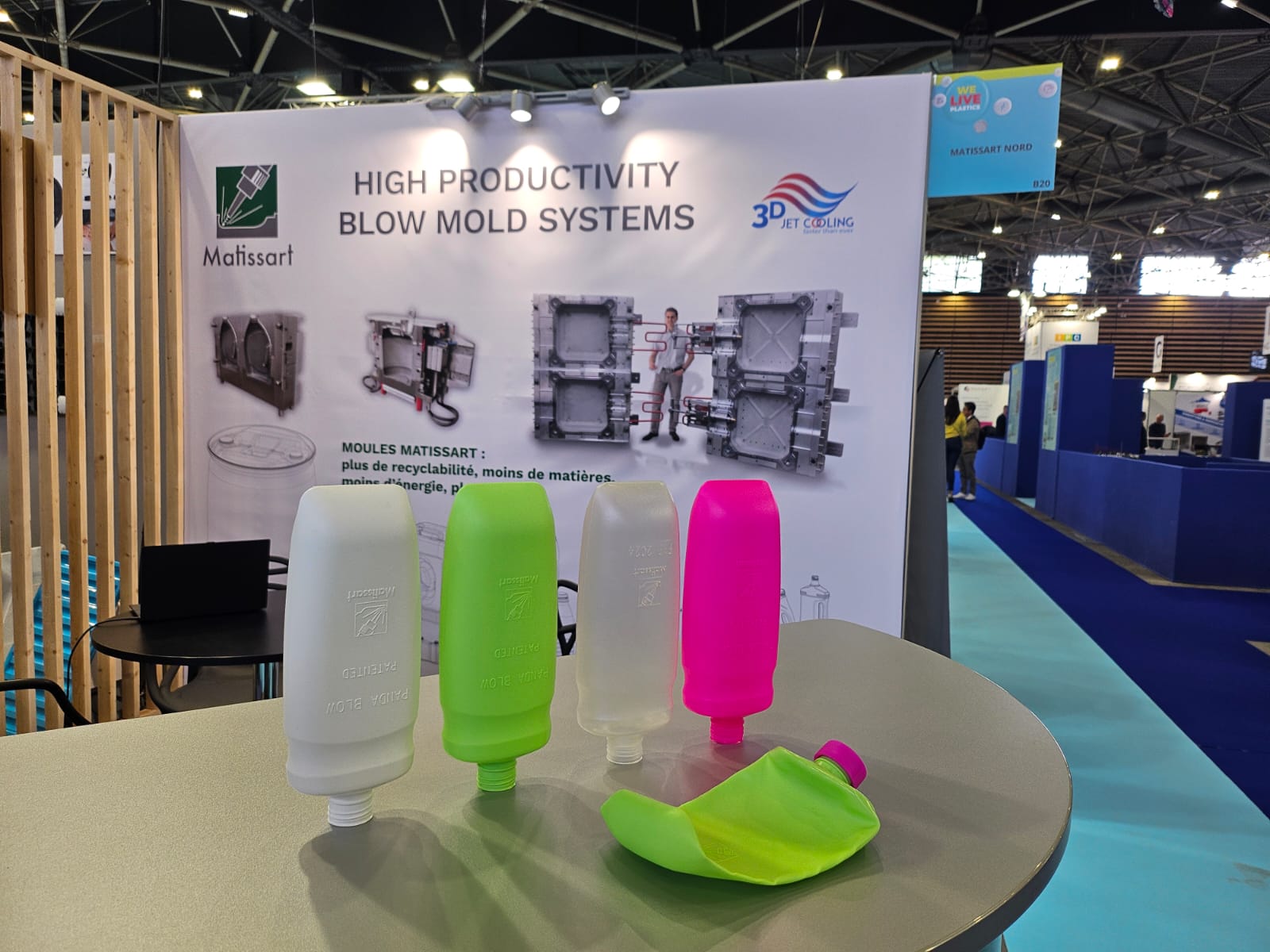

2. Breakthrough in 3D-Integrated Cooling

Complex cooling channels produced via metal 3D printing (SLM, DMLS) or through MATISSART’s 3D JET COOLING technology enable:

- homogeneous cooling,

- a substantial reduction in hot spots,

- improved blowing consistency,

- enhanced dimensional accuracy.

For extrusion-blow molds, this means:

- fewer internal stresses

- improved repeatability

- more stable cycles

3. Five-Axis Machining & Hyper-Finishing: The New Standard

High-speed 5-axis machining centers, combined with coated carbide or CBN tooling, offer:

- more complex geometries,

- very fine surface finishes,

- higher precision on functional areas,

- reduced manual polishing.

Conclusion

Innovations in metallurgy are no longer optional—they directly determine the performance of technical molds.

PMEs like MATISSART, capable of mastering new steels, 3D simulation, high-precision machining, and advanced cooling architecture, have become indispensable technical partners on the market.