In early 2024, the French government unveiled its new national roadmap on recycling and circular economy, with ambitious targets:

- 100% recyclable plastics by 2025

- 50% recycled plastics in packaging by 2030

For extrusion-blow molding manufacturers, this shift represents not only a change of paradigm but also a strategic opportunity.

1. Market Shift: Recycled Content Becomes a Key Commercial Criterion

Brands and retailers will now be required to demonstrate:

- the percentage of recycled content used,

- the true recyclability of their packaging,

- the traceability of their recycling streams.

This accelerates demand for:

- high-quality recycled HDPE (rHDPE),

- post-consumer rPP,

- mono-material solutions.

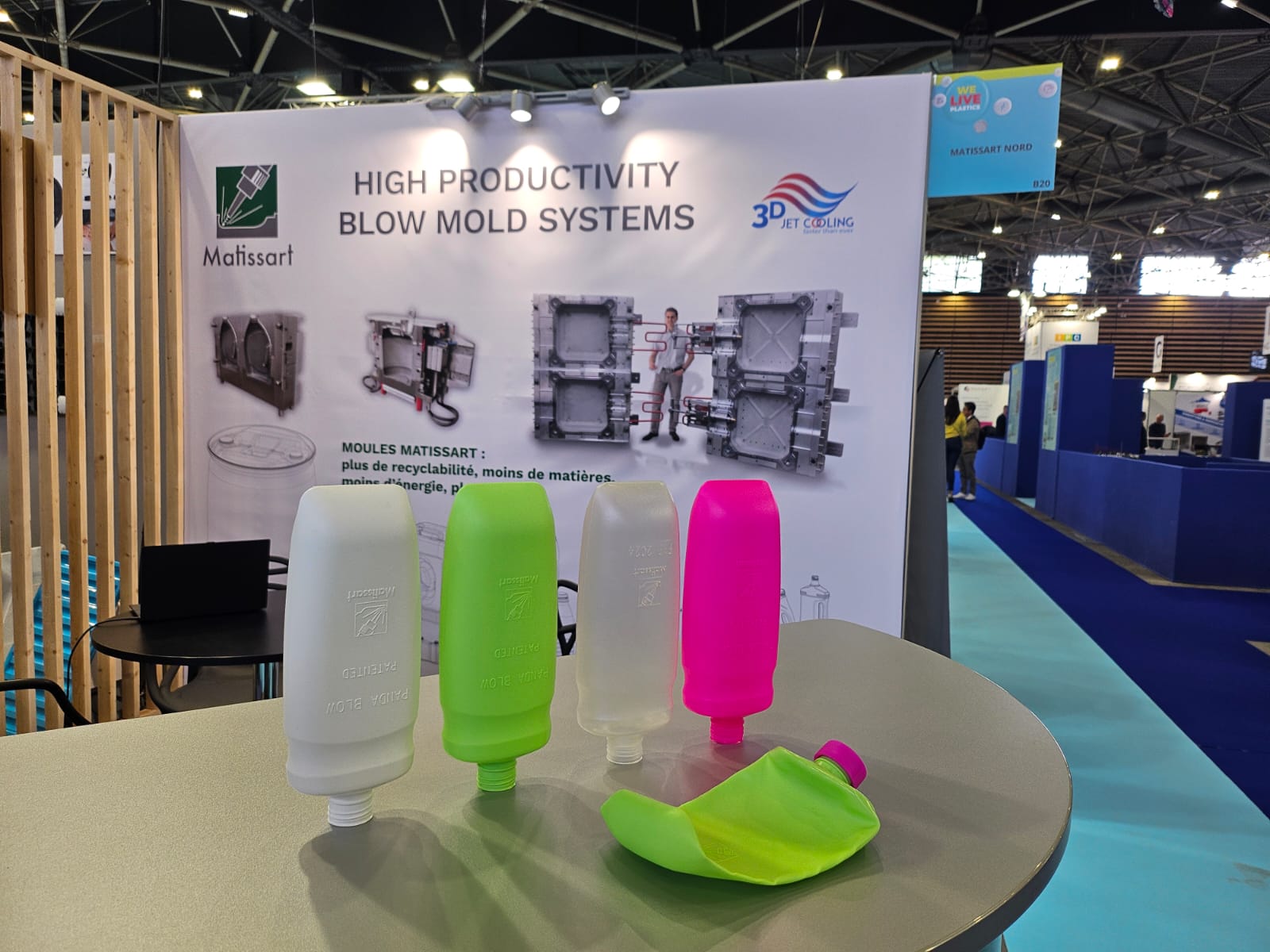

➡ PMIs like MATISSART, able to quickly adapt tooling and formulations, will be major winners in this transition.

2. Extrusion-Blow Molding: A Core Process in the Transition

French blow-molding manufacturers are being asked to:

- optimize weight reduction and rigidity,

- design mono-material packaging,

- develop geometries that improve recyclability,

- integrate increasing levels of PCR while maintaining mechanical performance.

Thanks to innovations in:

- high-precision dies,

- improved cooling systems,

- optimized molds (jet cooling, lightweight structures),

the sector is positioning itself as a major player in industrial decarbonization.

Extrusion-blow SMEs like MATISSART have a key advantage: ➡ reactivity + field expertise + strong innovation capability.

Conclusion

In an increasingly demanding regulatory environment, companies like MATISSART that anticipate market evolution—lightweighting, PCR integration, energy optimization—will significantly strengthen their competitiveness.

Extrusion-blow molding is emerging more than ever as a future-proof, sustainable process driving France’s ecological transition.